Genvan liquid silicone rubber

Generate your Vantage

Genvan Silicone Group Company is the leading liquid silicone rubber (LSR) manufacturer and supplier in China. Genvan, founded in January 2008, till now it has four manufacturing bases at Dongguan, Hubei, and Shenzhen. With the operation of Hubei automatic factory, it produces over 10000MT LSR annually.

Honored as the “Model Enterprise in Chinses Fluorosilicon Industry”, Genvan devotes itself to consistently deliver innovative new materials with better performance. All the time, it sticks to the standards: Green, Remarkable Quality, Outstanding Service, Consistent Innovation. By sustained investing in hardware, software of R&D and human resources, it not only offers customization according to requirement variety, but also has a fast reaction system to help customer to get what they need efficiently. Because of the industry-leading quality and service, the application and development of our products involve more than a dozen important areas. Genvan LSR has following vantages and features:

1. None post-curing LSR products: mainly used in infant and kitchenware products. About common liquid silicone rubber, without 200ºC and 4 hours post-curing, the VOC is at 1% to 1.2%, greater than LFGB standard: 0.5%. Genvan reduce the VOC to less than 0.5% without secondary curing, saving your time and money, reducing the emission.

2. Medical grade LSR products: mainly used in healthcare equipment and wearing accessories. Genvan’s anti-allergy LSR has passed 5 biocompatibility testing, anti-bacterial testing, and anti-mold testing. It is completely saft to contact with human skin.

3. Silicone rubber for wire and cable of new energy vehicle: mainly used in heat-resistant and flame-retardant cables for new energy vehicles, compliance with the standard EN50382-1:2008+A1:2013. It has been widely used by BYD and other new energy vehicle brands.

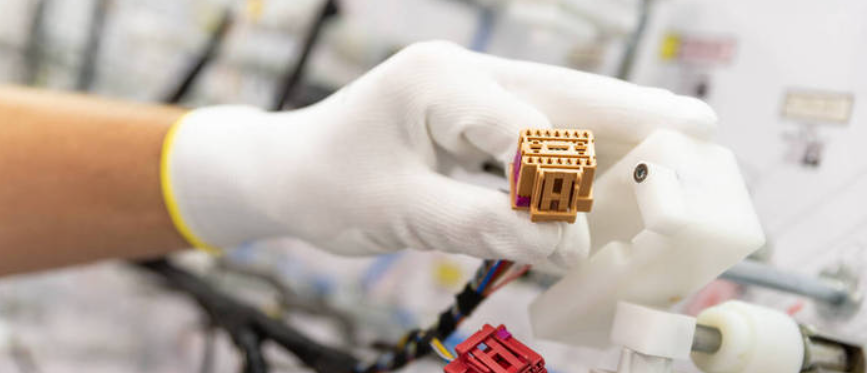

4. Self-lubricating liquid silicone rubber: mainly used in automotive wiring harness, 3C electronic accessories, with adjustable oil content and oil-bleeding speed according to customer requirements.

5. Silicone rubber for electric-power accessories: mainly used in cold shrink sleeve, insulation cable, plug head, transformer protective sleeve etc., pass tracking resistance test IEC 60587 1A3.5 and 1A4.5, tensile deformation within 8%.

6. Self-adhesive LSR: mainly used in wearing accessories, 3C electronic accessories, can be tightly bonded to various plastic and glass materials by one single molding without glue, very helpful to automated production process.

Popular Silicone Rubber Products

-

HTV Silicone Rubber

-

General HTV

- General Purpose Silicone Rubber For Molding (Precipitated/Fumed)

- High Strength Silicone Rubber

- Highly Anti-yellowing Silicone Rubber (Precipitated/Fumed)

- High Tear Strength Silicone Rubber for Molding (Precipitated/Fumed)

- High Resilience Fumed Silicone Rubber

- High-Transparent Fumed Silicone Rubber

- General Purpose Silicone Rubber For Extrusion (Precipitated/Fumed)

-

Advanced HTV

- High Hardness Silicone Rubber

- Low Hardness Silicone Rubber

- 2mm Flame Retardant Silicone Rubber

- High Strength Flame Retardant Silicone Rubber

- Flame Retardant Silicone Rubber (1mm: UL Yellow Card Cetificated)

- Silicone Rubber For Green Car

- Silicone Rubber for Cable Accessories (DBPMH/Platinum)

- Platinum Catalyzed Silicone Rubber For Extrusion

- Platinum Catalyzed Silicone Rubber For Molding

- Platinum Catalyzed Silicone Rubber for Medical Products

- Long Service Life Silicone Rubber for Buttons

- Antistatic Silicone Rubber (Precipitated/Fumed)

- Antistatic Silicone Rubber (Natural Color/Black)

- Oil-bleeding Silicone Rubber (Precipitated/Fumed)

- Thermally Conductive Silicone Rubber

- Oil Resistant Silicone Rubber

- Low Compression Set Silicone Rubber (Precipitated/Fumed)

- Heat Resistant Silicone Rubber (250 and 300 centigrade Degree)

- Hot Stamping Roll Silicone Rubber

- Heat Resistant and Flame Retardant Silicone Rubber

- Antibacterial silicone rubber (Precipitated/Fumed)

-

General HTV

-

Liquid Silicone Rubber

- General LSR

-

Advanced LSR

- Non-post-curing Liquid Silicone Rubber

- Liquid Silicone Rubber For Cable Accessories

- Selective Self-Adhesive Liquid Silocone Rubber

- Low Viscosity Liquid Silicone Rubber

- Optical Liquid Silicone Rubber

- Self-Lubricating Liquid Silicone Rubber

- Liquid Silicone Rubber For Molding

- Liquid Silicone Rubber For Medical

- Liquid Silicone Rubber For Coating

- Antibacterial Liquid Silicone Rubber

-

- What Is LSR?

-

Genvan liquid silicone rubber

Generate your Vantage - Home

- Company Profile

- FAQ

- HTV Silicone Rubber

- Clear Liquid Silicone Rubber

- Industrial

- HTV Silicone Rubber

- General Purpose Silicone Rubber For Molding Fumed

- What Is HCR?

- Join with EP Power Show to create a new engine for the industry

- Products

- Medical

- Document Download

- Liquid Silicone Rubber

- High Strength Liquid Silicone Rubber

- General Purpose Silicone Rubber For Molding Precipitated

- Genvan Is One Of The Raw Material Manufacturers Of Bing Dwen Dwen

- Liquid Silicone Rubber

- Happy Women's Day

- Silicone Innovation

- About Us

- Automotive

- Blog

- General Purpose Liquid Silicone Rubber (Precipitated/Fumed)

- High Strength Silicone Rubber

- LSR Liquid Silicone Rubber

- Wide Application Of Silicone Products In The Medical Industry

- Dongguan Genvan Silicone Technology Co., LTD., subsidiary of Genvan Group, wins the title of National SRDI "Little Giant" Enterprise!

- Applications

- Electronics

- Silicones Wiki

- Liquid Silicone Rubber For Baby Care

- High-Anti-Yellowing Silicone Rubber Fumed

- 2022, Genvan Will Build Dreams Of The Future!

- LSR Liquid Silicone

- Method For Improving Heat Resistance And Flame Retardancy Of Silicone Rubber

- Company News

- Resources

- Domestic Products

- Video

- General Purpose Silicone Rubber For Molding (Precipitated/Fumed)

- Non-post-curing Liquid Silicone Rubber

- High-Anti-Yellowing Silicone Rubber Precipitated

- Silicone Rubber Company Video

- 8 Reasons Why Silicone Rubber is the Best Material for Medical Device Design

- Genvan Silicone attends the Honai International Maternity, Baby & Kids Fair

- Contact Us

- Quality Control

- High Strength Silicone Rubber

- Liquid Silicone Rubber For Cable Accessories

- High Tear Strength Silicone Rubber for molding Fumed

- Silicone Rubber Factory Video

- Composition of Silicone Rubber | Main Features and Uses of Silicone Rubber Products

- Search Result

- Highly Anti-yellowing Silicone Rubber (Precipitated/Fumed)

- Selective Self-Adhesive Liquid Silocone Rubber

- High Tear Strength Silicone Rubber for molding Precipitated

- Silicone Rubber Manufacturer Video

- Processing Technology of Silicone Rubber

- Low Viscosity Liquid Silicone Rubber

- Search Result Products

- High Resilience Fumed Silicone Rubber

- Silicone Rubber Supplier Video

- Different Grades of Silicone Rubber Products | Why Do Many People Choose Medical Grade Silicone?

- High Tear Strength Silicone Rubber for Molding (Precipitated/Fumed)

- Optical Liquid Silicone Rubber

- Search Result Others

- High-Transparent Fumed Silicone Rubber Fumed

- How to Distinguish Ordinary Silicone and Platinum Silicone Products?

- Genvan Silicone

- Sitemap

- High Resilience Fumed Silicone Rubber

- Self-Lubricating Liquid Silicone Rubber

- General Purpose Silicone Rubber For Extrusion Fumed

- The Difference Between Food Grade and Medical Grade Silicone

- 404

- High-Transparent Fumed Silicone Rubber

- Liquid Silicone Rubber For Molding

- General Purpose Silicone Rubber For Extrusion Precipitated

- Safety Performance of Medical Silicone

- Privacy Policy

- General Purpose Silicone Rubber For Extrusion (Precipitated/Fumed)

- Liquid Silicone Rubber For Medical

- High Hardness Silicone Rubber

- What is Liquid Silicone?

- Submission Successful!

- High Hardness Silicone Rubber

- Liquid Silicone Rubber For Coating

- Low Hardness Silicone Rubber

- What Are the Main Factors That Affect the Surface Stickiness of Silicone Products?

- Taggg

- Low Hardness Silicone Rubber

- Antibacterial Liquid Silicone Rubber

- 2mm Flame Retardant Silicone Rubber

- Four Characteristics of High Temperature Cables

- 2mm Flame Retardant Silicone Rubber

- High Strength Flame Retardant Silicone Rubber

- What Are the Applications and Functions of Silicone Rubber Products in the Automotive Industry?

- High Strength Flame Retardant Silicone Rubber

- Flame Retardant Silicone Rubber (1mm, UL Yellow Card Cetificated)

- Why Are Silicone Products So Popular?

- Flame Retardant Silicone Rubber (1mm: UL Yellow Card Cetificated)

- Silicone Rubber For Cable Accessories

- What Are the Differences between Liquid Silicone and Solid Silicone?

- Silicone Rubber For Green Car

- What Are the Definitions of Medical Silicone Materials?

- Silicone Rubber for Cable Accessories (DBPMH/Platinum)

- Platinum Catalyzed Silicone Rubber For Extrusion

- Application of Silicone Rubber Products in Various Industries

- Platinum Catalyzed Silicone Rubber For Extrusion

- Platinum Catalyzed Silicone Rubber For Molding

- Analysis of Reasons for Yellowing of Transparent Silicone Rubber

- Platinum Catalyzed Silicone Rubber For Molding

- Platinum Catalyzed Silicone Rubber For Medical

- What to Consider When Using Silicone Rubber in the Automotive Industry?

- Platinum Catalyzed Silicone Rubber for Medical Products

- Long Service Life Silicone Rubber for Buttons

- Application of Silicone Rubber Materials in Medical Devices

- Long Service Life Silicone Rubber for Buttons

- Ingredients and Characteristics of Medical Silicone

- Antistatic Silicone Rubber (Precipitated/Fumed)

- Application and Characteristics of Silicone Rubber

- Antistatic Silicone Rubber (Natural Color/Black)

- Antistatic Silicone Rubber Black

- Advantages of Liquid Rubber Compared to Solid Rubber

- Oil-bleeding Silicone Rubber (Precipitated/Fumed)

- What Are the Features of Cable Silicone?

- Thermally Conductive Silicone Rubber

- Oil-bleeding Silicone Rubber-Fumed

- Application of Typical Silicone Rubber Parts in Automobiles

- The Characteristics of Silicone Rubber and the Automotive Industry's Demands for It

- Oil Resistant Silicone Rubber

- Oil-bleeding Silicone Rubber-Precipitated

- What Are the Molding Processes of Liquid Silicone Rubber?

- Low Compression Set Silicone Rubber (Precipitated/Fumed)

- Thermal Conductivity Silicone Rubbers

- What Are the Requirements and Advantages of Medical-Grade Silicone Molding Technology?

- Heat Resistant Silicone Rubber (250 and 300 centigrade Degree)

- Oil Resistant Silicone Rubber

- What Is the Difference Between Medical-Grade Silicone Products and Regular Silicone?

- Hot Stamping Roll Silicone Rubber

- Oil-bleeding Silicone Rubber Fumed

- Why do Most Medical Silicone Products Use Liquid Silicone?

- Heat Resistant and Flame Retardant Silicone Rubber

- Oil-bleeding Silicone Rubber Precipitated

- Application of Silicone on Car Lights

- Antibacterial silicone rubber (Precipitated/Fumed)

- Low Compression Set Silicone Rubber Fumed

- The Difference Between Food-Grade Silicone and Regular Silicone

- Low Compression Set Silicone Rubber Precipitated

- Production and Common Applications of Medical Silicone

- Heat Resistant Silicone Rubber (250 And 300 Centigrade Degree)GA-60X1A Series

- Reasons for the Reduction of Insulation Performance in Cable Silicone Rubber

- Heat Resistant Silicone Rubber (250 And 300 Centigrade Degree)GA-60X1F Seires

- Cable Silicone Environmental Protection Is an Industry Trend

- Hot Stamping Roll Silicone Rubber

- Does Higher Transparency of Medical Grade Silicone Tubing Indicate Better Quality?

- Heat Resistant And Flame Retardant Silicone Rubber

- Application of Silicone Rubber in New Energy Vehicles

- Antibacterial Silicone Rubber Fumed

- Why Is Medical Silicone Rubber Tubing Unique in the Field of Medicine?

- Antibacterial Silicone Rubber Precipitated

- Development Prospects of Medical Silicone

- An Introduction to the Medical Applications of Medical Silicone Hose

- How Much Do You Know About Medical Silicone Rubber Products?

- Design of Rubber Shock-Absorbing Components for Automobile Chassis

- Car Rubber Materials and Engine Suspension Damping System

- Application of Heat-resistant Silicone in Automotive Industry and Aerospace Field

- Performance Requirements of Car Silicone for Turbocharged Systems

- How Liquid Silicone Rubber Coating Can Improve Product Performance?

- What Is Oil Proof Rubber?

- The Benefits of Liquid Silicone Rubber Coating for Industrial Applications

- Applications of Oil Proof Rubber

- The Future of Liquid Silicone Rubber Coating: Innovations and Advancements

- How Heat-Conductive Silicone Rubber is Revolutionizing the Electronics Industry?

- Innovative Applications of Heat-Conductive Silicone Rubber for Thermal Management

- How to Choose the Right Flame Retardant Silicone Rubber for Your Project?

- The Science Behind Flame Retardant Silicone Rubber and How it Works

- The Benefits of Antimicrobial Silicone Rubber for Medical Devices

- How Does Platinum Catalyzed Silicone Rubber Compare to Other Types of Rubber?

- MSDS-General Purpose Silicone Rubber For Extrusion Fumed

- Common Uses of Platinum Catalyzed Silicone Rubber in Various Industries

- MSDS-General Purpose Silicone Rubber For Extrusion Precipitated

- Top 5 Uses of Heat Conductive Silicone Rubber in Industrial Applications

- MSDS-General Purpose Silicone Rubber For Molding Fumed

- Choosing the Right Heat Conductive Silicone Rubber: Factors to Consider

- MSDS-General Purpose Silicone Rubber For Molding Precipitated

- Exploring the Advantages of Heat Conductive Silicone Rubber in Electronic Devices

- MSDS-High Resilience Fumed Silicone Rubber

- Understanding the Curing Process of Platinum Catalyzed Silicone Rubber

- MSDS-High Strength Silicone Rubber

- The Ultimate Guide to Platinum Catalyzed Silicone Rubber: Properties and Applications

- MSDS-High Tear Strength Silicone Rubber for Molding Fumed

- Heat Conductive Silicone Rubber vs. Traditional Thermal Interface Materials: A Comparative Analysis

- MSDS-High Tear Strength Silicone Rubber for Molding Precipitated

- What is Medical Grade Liquid Silicone and Its Applications in Healthcare?

- MSDS-High-Anti-Yellowing Silicone Rubber Fumed

- Is Medical Grade Liquid Silicone Safe for Use in Implants?

- MSDS-High-Anti-Yellowing Silicone Rubber Precipitated

- The Role of Medical Grade Liquid Silicone in Medical Wearables

- MSDS-High-Transparent Fumed Silicone Rubber Fumed

- What is Fuel Proof Rubber and Why is it Important in Automotive Applications?

- MSDS-2mm Flame Retardant Silicone Rubber

- Effect of Curative Systems on the Properties of High Temperature Resistant Silicone Rubber

- MSDS-Antibacterial Silicone Rubber-Fumed

- Manufacturing Technologies for High Temperature Resistant Silicone Rubber

- MSDS-Antistatic Silicone Rubber Black

- Design and Optimization of Petrol Resistant Rubber Products for Automotive and Industrial Applications

- MSDS-Antistatic Silicone Rubber Fumed

- Multi-Functional Properties of High Tear Strength Silicones

- MSDS-Antistatic Silicone Rubber Natural Color

- Applications of High Tear Strength Silicones in Medical and Healthcare Industries

- MSDS-Antistatic Silicone Rubber Precipitated

- Properties and Applications of Petrol Resistant Rubber

- Future Directions and Challenges in Low Viscosity Silicone Rubber Research and Development

- MSDS-Flame Retardant Silicone Rubber (1mm, UL Yellow Card Cetificated)

- Low Viscosity Silicone Rubber for High-Performance Coatings and Adhesives

- MSDS-Heat Resistant and Flame Retardant Silicone Rubber

- Quality Control and Assurance in Silicone Rubber Baby Mold Production

- MSDS-Heat Resistant Silicone Rubber (250 and 300 Centigrade Degree)

- Design Considerations for Silicone Rubber Baby Molds

- MSDS-High Hardness Silicone Rubber

- Processing and Manufacturing Techniques for Optically Clear Liquid Silicone Rubber

- MSDS-High Strength Flame Retardant Silicone Rubber

- Optical Properties of Optically Clear Liquid Silicone Rubber

- MSDS-Hot Stamping Roll Silicone Rubber

- The Heat Resistance of Silicone Rubber

- MSDS-Long Service Life Silicone Rubber for Buttons

- Unleashing the Power of Fuel-Proof Silicone: Protecting Your Equipment and Components

- MSDS-Low Compression Set Silicone Rubber Fumed

- Step-by-Step: How to Apply Silicone to Your Car Windshield for a Perfect Seal

- MSDS-Low Compression Set Silicone Rubber Precipitated

- Why Silicone is the Perfect Sealant for Your Car Windshield?

- MSDS-Low Hardness Silicone Rubber

- Choosing the Right Silicone for Your Car Windshield: Factors to Consider

- MSDS-Oil Resistant Silicone Rubber

- Fuel-Proof Silicone: Versatile Applications for Ultimate Protection

- MSDS-Oil-Bleeding Silicone Rubber Fumed

- How to Choose the Right Fuel-Proof Silicone for Your Needs?

- MSDS-Oil-Bleeding Silicone Rubber Precipitated

- Silicone Flame Retardant: Understanding its Importance and Applications

- MSDS-Platinum Catalyzed Silicone Rubber For Extrusion

- How to Test and Certify the Effectiveness of Silicone Flame Retardant?

- MSDS-Platinum Catalyzed Silicone Rubber For Medical

- Common Uses of Silicone Flame Retardant in Electrical and Electronic Industries

- MSDS-Platinum Catalyzed Silicone Rubber For Molding

- MSDS-Silicone Rubber for Cable Accessories Platinum

- MSDS-Silicone Rubber for Cable Accessories-DBPMH

- MSDS-Silicone Rubber For Green Car

- MSDS-Thermal Conductivity Silicone Rubber

- MSDS-General Purpose Liquid Silicone Rubber Fumed

- MSDS-General Purpose Liquid Silicone Rubber Precipitated

- MSDS-Clear Liquid Silicone Rubber

- MSDS-High Strength Liquid Silicone Rubber

- MSDS-Liquid Silicone Rubber For Baby Care

- MSDS-Addition Cure Liquid Silicone Rubber For Molding

- MSDS-Antibacterial Luquid Silicone Rubber

- MSDS-Liquid Silicone Rubber For Cable Accessories

- MSDS-Liquid Silicone Rubber For Coating

- MSDS-Liquid Silicone Rubber For Medical

- MSDS-Low Viscosity Liquid Silicone Rubber

- MSDS-Non-post Cure Liquid Silicone Rubber

- MSDS-Optical Liquid Silicone Rubber

- MSDS-Selective Self-Adhesive Liquid Silocone Rubber

- MSDS-Self-Lubricating Liquid Silicone Rubber

- MSDS-General Purpose Silicone Rubber For Molding Precipitated

- MSDS-antibacterial Silicone Rubber

中文

中文